What Is Enerfit?

Enerfit is a retrofit for single-zone rooftop commercial air conditioning units that will cut the annual air conditioning electrical consumption in half or better.

Combining 21st century DDC controls and HTML 5 monitoring and analytics with the historical groundwork of Willis Carrier in the early 20th century, it is a potent mix of new technology and proven HVAC principles.

Combining 21st century DDC controls and HTML 5 monitoring and analytics with the historical groundwork of Willis Carrier in the early 20th century, it is a potent mix of new technology and proven HVAC principles.

Enerfit always includes an advanced controller, a VFD (variable frequency drive) and a set of precision sensors built specifically for the unit being retrofitted.

Enerfit can be deployed on any direct expansion RTU that is single-zone (not VAV) and has a three-phase evaporator fan motor (typically seen on units six tons and larger) or ECM. It is compatible with split systems, geothermal units, CRAC units and heat pumps.

Enerfit can be deployed on any direct expansion RTU that is single-zone (not VAV) and has a three-phase evaporator fan motor (typically seen on units six tons and larger) or ECM. It is compatible with split systems, geothermal units, CRAC units and heat pumps.

There is no size limitation - some of the most aggressive payback opportunities seen to date are on units over 100 tons.

How Does It Work?

Enerfit controls the indoor (evaporator) fan speed in response to the operating mode of the unit. In cooling mode, Enerfit modulates the fan in real time to match conditions outdoors and in the conditioned space.

In cooling mode, the patented Enerfit algorithm to guarantee compressor safety and protection. The algorithm also allows the retrofit to safely turn down the evaporator fan speed far beyond any other VFD retrofit for RTUs.

In cooling mode, the patented Enerfit algorithm to guarantee compressor safety and protection. The algorithm also allows the retrofit to safely turn down the evaporator fan speed far beyond any other VFD retrofit for RTUs.

If a unit is not functioning properly (dirty coils, high/low suction pressures, etc), Enerfit will initiate alarms and modulate the fan speed as necessary to protect the compressors.

While it does not modify ANY factory RTU safeties, Enerfit does add several additional safeguards and will shut down the entire RTU in the case of phase failure, phase reversal, high and low voltage spikes or ground faults that could permanently damage the unit.

What's the End Result?

After years of testing in multiple climates, a wide range of RTU sizes and configurations, Enerfit typically saves at least 50% of the total annual electrical consumption of the unit.

In cases where the units are very oversized - often because of cautious engineering or where lighting retrofits have reduced the heat load - we have seen savings well in excess of 50%.

kWd - Kilowatt Demand

The design of Enerfit transforms the RTU into a non-overloading dehumidifier which is an asset during mandatory kW reduction periods.

The RTU will continue to dehumidify the space during the mandatory period (generally the hottest day of the year). This dehumidification makes elevated space temperatures more comfortable as well as shortening the recovery time once the mandatory period is over.

The RTU will continue to dehumidify the space during the mandatory period (generally the hottest day of the year). This dehumidification makes elevated space temperatures more comfortable as well as shortening the recovery time once the mandatory period is over.

Enerfit generates additional demand savings by reducing the compression ratio of the compressors. The further the outdoor temperature falls below the outdoor design temperature (i.e. almost all of the time) the more the compression ratio is reduced.

This is due to the fact that Enerfit algorithm maintains a stable suction pressure which also keeps the compressors operating safely and at maximum efficiency.

This is due to the fact that Enerfit algorithm maintains a stable suction pressure which also keeps the compressors operating safely and at maximum efficiency.

Space Relative Humidity & Occupant Comfort

Because of its patented control algorithm, Enerfit limits the relative humidity in the space by roughly 15% utilizing passive dehumidification during the mechanical cooling mode in moderate and humid climates.

Passive dehumidification has a long history tracing all the way back to Willis Carrier's early work on psychrometrics in the early 20th century.

In the case of Enerfit, by maintaining both the temperature in the space by staging compressors and controlling the temperature of the air leaving the cooling coil by varying the fan speed, the relative humidity will be consistently limited to a maximum value.

In the case of Enerfit, by maintaining both the temperature in the space by staging compressors and controlling the temperature of the air leaving the cooling coil by varying the fan speed, the relative humidity will be consistently limited to a maximum value.

In addition to limiting space relative humidity in the mechanical cooling mode, Enerfit also reduces drafts in the winter and shoulder months.

The overall result is dramatically improved occupant comfort and a decrease (or in many cases almost total elimination) of comfort complaints.

The overall result is dramatically improved occupant comfort and a decrease (or in many cases almost total elimination) of comfort complaints.

Unit Maintenance & Analytics

Enerfit uses an array of precision sensors to make fan speed and safety decisions. These points are made available to onboard displays and network control protocols.

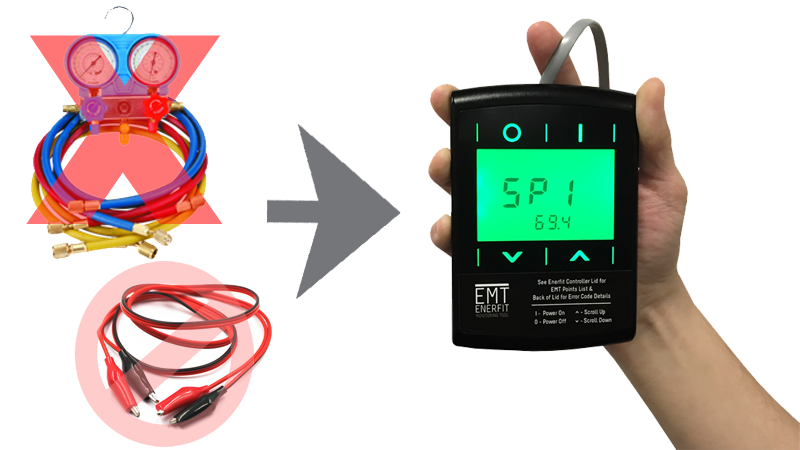

To assist HVAC technicians during startup or during service calls, the factory standard Enerfit Monitoring Tool (EMT) allows technicians to manually start and stop compressors and heat, enable or disable the economizer, control the indoor fan speed, and stroke outside air and evaporator coil face dampers.

To assist HVAC technicians during startup or during service calls, the factory standard Enerfit Monitoring Tool (EMT) allows technicians to manually start and stop compressors and heat, enable or disable the economizer, control the indoor fan speed, and stroke outside air and evaporator coil face dampers.

Both live service technicians and analytics software/BAS systems can instantly see suction pressures, coil temperatures, proactive alarms and over a dozen other points. The standard Enerfit controller ships with full support for BACnet MS/TP and BACnet IP.

I’ve seen VFD retrofits for RTUs before - what makes Enerfit different?

Other VFD solutions use evaporator fan indexing during the mechanical cooling mode (the mode with generally the most run hours during the year).

Those solutions either make an arbitrary/blind guess at how much they can slow down the fans or the speeds are set based on the weather at the time the unit was started up. Those fixed fan speed values are then locked in to the VFD.

Unlike Enerfit, there is no ability for fan indexing to change fan speeds to account for different indoor and outdoor temperatures or humidity conditions.

Those solutions either make an arbitrary/blind guess at how much they can slow down the fans or the speeds are set based on the weather at the time the unit was started up. Those fixed fan speed values are then locked in to the VFD.

Unlike Enerfit, there is no ability for fan indexing to change fan speeds to account for different indoor and outdoor temperatures or humidity conditions.

Enerfit's patented control methodology looks at and adjusts the fan speed to limit the relative humidity. This methodology also ensure compressor safety and maximizes evaporator fan savings.

The substantially greater evaporator fan savings, when compared to fan indexing, (coupled with their reduction of fan heat and relative humidity) make Enerfit’s performance unmatched for sites in mild and humid climates.

Exactly How Does Enerfit Save So Much Energy?

1. It saves 85%+ total annual fan energy.

2. It transforms the RTU into a non-overloading dehumidifier during mandatory demand reduction periods while still saving energy.

3. Substantially reduced evaporator fan heat yields compounded compressor savings in cooling mode.

4. Improves the compression ratio of the compressors below design ambient temperatures which saves compressor energy.

2. It transforms the RTU into a non-overloading dehumidifier during mandatory demand reduction periods while still saving energy.

3. Substantially reduced evaporator fan heat yields compounded compressor savings in cooling mode.

4. Improves the compression ratio of the compressors below design ambient temperatures which saves compressor energy.

What about Economizers / Utility Rebates?

The Enerfit controller comes with an optional economizer control that can meet California Title 24 dry bulb comparison control (typical for Western US) or for enthalpy comparison economizer control (typical for Eastern US).

The Enerfit solution is integrated into the primary controller and is engineered to allow for a simple, fast, and accurate installation.

The Enerfit Demand Controlled Ventilation (DCV) economizer option is particularly attractive in colder climates where the heating savings can be very substantial.

The Enerfit Demand Controlled Ventilation (DCV) economizer option is particularly attractive in colder climates where the heating savings can be very substantial.

Next Steps

If you're interested in learning more about Enerfit you can contact our sales team here.